| Sign In | Join Free | My frbiz.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My frbiz.com |

|

Place of Origin : Hunan, China

Brand Name : Zhuzhou Jintai Cemented Carbide

Model Number : Various

Supply Ability : 300 Ton/Tons per Month

Packaging Details : Pack with shock resistance foam first in plastic box, and then carton boxes outside. Or pack according to your request

MOQ : 1 - 1000 Kilograms, sample order acceptable

Price : Negotiable, depends on carbide grade and quantity.

Delivery Time : 7-25 days, depends on quantity

Certification : SGS certificated

Payment Terms : Western Union, L/C, T/T

Alloy Specification : YG6X/YG8/YL10.2 ETC...

Particle : 0.2-1.7um

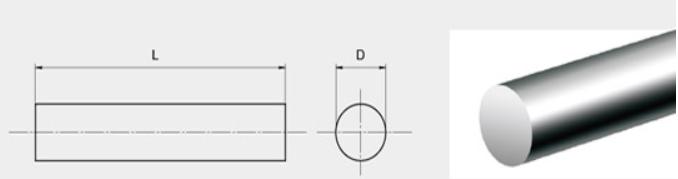

Product name : cemented carbide rods yl10.2 solid tungsten carbide round bars

Material : 100% virgin carbide material

Surface : High Polished

Certificate : ISO

Usage : endmills, cutting holder,weaterjet

Advantage : High density, Excellent Wear Resistance,high bending strength

Better wear resistance, higher toughness, better deformation and fracture resistance,

Appication

Applicable in make the drill bits, end-mills, reamers, automobile special cutters, printed circuit board special cutters, engine special cutters, Horologe processing special cutters, integral vertical milling cutter, graver and etc. Besides, it can be used for making of cemented carbide stamping head, Core bar and perforatioin tools.

| Properties of cemented carbide grades recommended rods | |||||||

| Grade | Chemical composition | Physical data | Grain size of WC(um) | ||||

| WC | Co | Others | Density(g/cm³) | Hardness(HV3) | TRS(MPa) | ||

| YL10.1 | 93.50% | 6.00% | 0.50% | 14.88-15.04 | 1580±50 | 2500 | 1.2-1.7 |

| YL10.2 | 89.50% | 10.00% | 0.50% | 14.4-14.55 | 1600±50 | 4000 | 0.8 |

| YL10.5 | 89.70% | 9.50% | 0.80% | 14.4-14.55 | 1550±50 | 3800 | 0.7-0.9 |

| YL50 | 85.00% | 15.00% | 13.86-14.10 | 1095 | 2060 | 0.4-0.6 | |

| YU06 | 93.00% | 6.00% | 1.00% | 14.7-14.8 | 2050 | 3000 | 0.2-0.4 |

| YU08 | 91.00% | 8.00% | 1.00% | 14.56-14.65 | 1900 | 4000 | 0.2-0.4 |

| YU09 | 89.80% | 9.00% | 1.20% | 14.36-14.50 | 1950 | 3900 | 0.2-0.4 |

| YU12 | 87.00% | 12.00% | 1.00% | 14.05-14.15 | 1750 | 4000 | 0.2-0.4 |

| YF06 | 93.50% | 6.00% | 0.50% | 14.86-14.96 | 1800 | 3800 | 0.4-0.6 |

| YF08 | 91.40% | 8.00% | 0.60% | 14.55-14.65 | 1800 | 3900 | 0.4-0.6 |

| YG6X | 93.50% | 6.00% | 0.50% | 14.8-15.10 | 91 | 1560 | 1 |

| YG8 | 92.00% | 8.00% | 14.6-14.9 | 89.5 | 1840 | 1.2-1.6 | |

~ Customized Tungsten carbide products are available!

| Type | D(mm) | Tol. Of diameter(mm) | L(mm) | Tol. Of diameter(mm) |

| ¢1.0*330 | 1.0 | +0.2~+0.45 | 330 | 0~+5.0 |

| ¢2.0*330 | 2.0 | +0.2~+0.45 | 330 | 0~+5.0 |

| ¢3.0*330 | 3.0 | +0.2~+0.45 | 330 | 0~+5.0 |

| ¢4.0*330 | 4.0 | +0.2~+0.45 | 330 | 0~+5.0 |

| ¢5.0*330 | 5.0 | +0.2~+0.45 | 330 | 0~+5.0 |

| ¢6.0*330 | 6.0 | +0.2~+0.45 | 330 | 0~+5.0 |

| ¢7.0*330 | 7.0 | +0.2~+0.45 | 330 | 0~+5.0 |

| ¢8.0*330 | 8.0 | +0.2~+0.45 | 330 | 0~+5.0 |

| ¢9.0*330 | 9.0 | +0.2~+0.45 | 330 | 0~+5.0 |

| ¢10.0*330 | 10.0 | +0.2~+0.5 | 330 | 0~+5.0 |

| ¢11.0*330 | 11.0 | +0.2~+0.5 | 330 | 0~+5.0 |

| ¢12.0*330 | 12.0 | +0.2~+0.5 | 330 | 0~+5.0 |

| ¢13.0*330 | 13.0 | +0.2~+0.5 | 330 | 0~+5.0 |

| ¢14.0*330 | 14.0 | +0.2~+0.5 | 330 | 0~+5.0 |

| ¢15.0*330 | 15.0 | +0.2~+0.6 | 330 | 0~+5.0 |

| ¢16.0*330 | 16.0 | +0.2~+0.6 | 330 | 0~+5.0 |

| ¢17.0*330 | 17.0 | +0.2~+0.6 | 330 | 0~+5.0 |

| ¢18.0*330 | 18.0 | +0.2~+0.6 | 330 | 0~+5.0 |

| ¢19.0*330 | 19.0 | +0.2~+0.6 | 330 | 0~+5.0 |

| ¢20.0*330 | 20.0 | +0.2~+0.7 | 330 | 0~+5.0 |

| ¢21.0*330 | 21.0 | +0.2~+0.7 | 330 | 0~+5.0 |

| ¢22.0*330 | 22.0 | +0.2~+0.7 | 330 | 0~+5.0 |

| ¢23.0*330 | 23.0 | +0.2~+0.7 | 330 | 0~+5.0 |

| ¢24.0*330 | 24.0 | +0.2~+0.7 | 330 | 0~+5.0 |

| ¢25.0*330 | 25.0 | +0.2~+0.7 | 330 | 0~+5.0 |

| ¢26.0*330 | 26.0 | +0.2~+0.8 | 330 | 0~+5.0 |

| ¢27.0*330 | 27.0 | +0.2~+0.8 | 330 | 0~+5.0 |

| ¢28.0*330 | 28.0 | +0.2~+0.8 | 330 | 0~+5.0 |

| ¢29.0*330 | 29.0 | +0.2~+0.8 | 330 | 0~+5.0 |

| ¢30.0*330 | 30.0 | +0.2~+0.8 | 330 | 0~+5.0 |

|

|

ISO Certificated Solid Carbide Round Blanks , Solid Carbide Rods Anti Corrosion Images |